Any Question at

Monday - Friday

8 am – 5 pm

Shibu Development Zone

weifang City, China.

Send your mail at

Air Compressor

The air compressor is the main body of the air source device of the blow molding machine, it is the mechanical energy of the prime mover (usually an electric motor) into gas pressure energy device, is a special air pressure generation device of the blowing machine after compressed air.

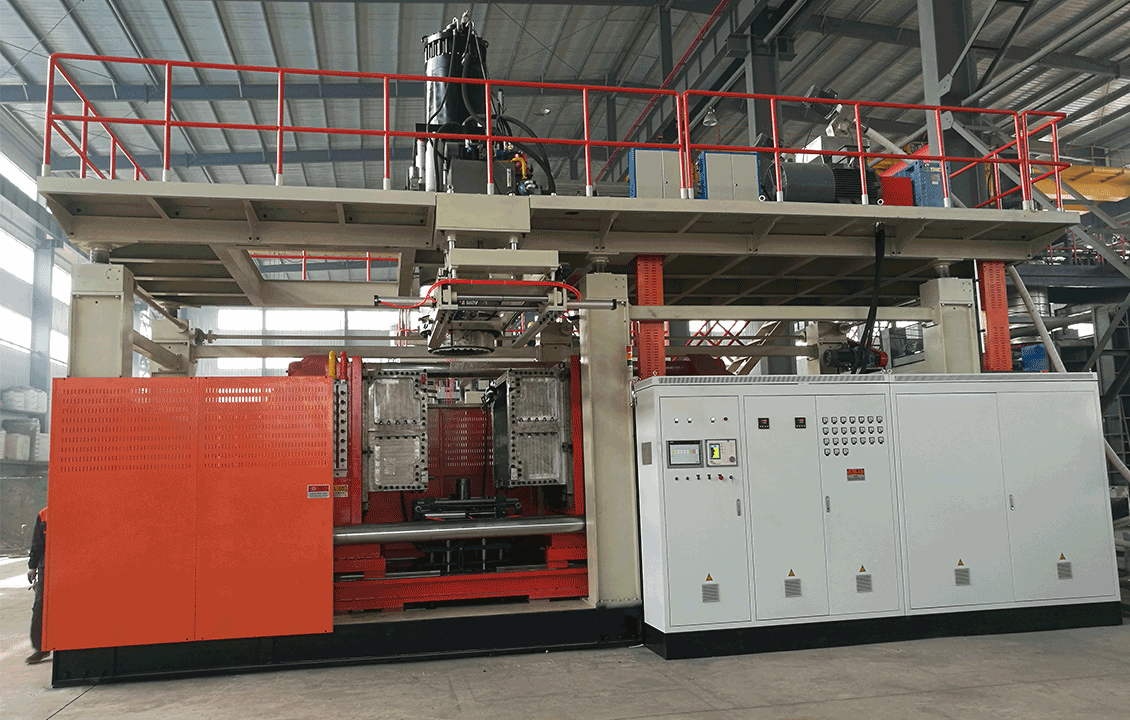

Blow molding machine

The raw material is extruded or injection molded to obtain a tubular shape, heated and softened, placed into a model (equivalent to a balloon skin), and then filled with compressed air (blowing), which is pressed against the inner wall of the mold, and cooled to obtain a variety of hollow plastic products.

Application areas of hollow blow molding machine: we usually see medicine bottles, children’s toys, beverage straws, balls and so on belong to small blow molding products, traffic facilities, large plastic barrels, double-ring barrels, IBC chemical ton drums, barricades, kayaks, solar lining and other belong to large blow molding machine products.

Visit our factory

We have rich experience in the aspects of air power, hydraulic technology and automatic control technology. We have excellent engineering technicians and a high quality customer service team. We can provide such services as investment analysis, machine choice, technology guidance and personnel training, etc. for our clients. We sincerely welcomes businessmen from all over the world to do business with us for common development.

Mechanical Usage

OUR ADVANTAGE

PRODUCT ADVANTAGE

Our company hollow blow molding machine adopts the latest technology and supporting facilities in the design and production process, such as: German SEW reducer, Siemens PLC controller, American Moog wall thickness controller, etc., To further optimize the overall performance of the equipment and expand the equipment application fields to ensure energy-saving and stable operation of equipment.

TECHNOLOGY ADVANTAGE

Our company has more than 20 years experience in the production and design of blow molding machines. We has large-scale machining centers.Such as large-scale floor-type boring and milling machines imported from Germany, large-scale gantry milling machines, and large-scale CNC lathes etc.,more than 30 sets of comprehensive machining equipment,which can grasp the precision of equipment processing from the source. The company puts scientific and technological innovation in a prominent position and has an experienced scientific and technological research and development team. At present, it has obtained more than 100 patent certificates and ISO9001 standard quality management system certification, SGS third-party certification,CE certification. It has incomparable advantages in the speed of technology research and development and product update.

SERVICE ADVANTAGE

Pre-sales, fully understand the various request of our customer.Help customer to choose the correct type of blow molding machine and auxiliary equipment.Reasonably plan customers’ water, electricity, gas, oil and other solutions.

On-sales,Arrange professional and technical engineer to help equipment operators installation and connect water and electricity of the blow molding machines with auxiliary equipment,to enable the equipment a standardized and safe manner to running. We also provide training the machine operators, so that operators can operate the blow molding machine skillfully and master the maintenance of the equipment.

After-sales,provide customers with technical guidance and continuous optimization of products for life.

2500 customers have been with us for a long time, with a five-year product warranty and engineers based overseas.

The following comments are just a few examples of the 2,500 customers worldwide